Tile History

Part 1: From the beginning of recorded history

The story of ceramics first began in Anatolia, a land which has been home to countless civilizations over the millennia; and where modern Turkey comes into being; in whose fertile soil different cultures have flourished; and which has witnessed the most important turning points in human history.

Part 2: Early uses of clay

Ceramic tile is made from similar clays found in pottery, statues and objects of art and religion. Clay objects have been found in many archaeological discoveries. The earliest pottery was primarily functional in character, in the form of vessels to hold the grain and other foodstuffs, which they produced, but clay was also used to make objects of religious significance. In time people learned to control the firing process better, and so produce ceramics of finer quality.

Invention of the potter’s wheel

While potters experimented with new forms, a new style of decoration consisting of the basic geometric motifs that were to be used for hundreds of years evolved. The discovery of the potter’s wheel in Mesopotamia and its introduction into Anatolia around 3000 BC opened a new era in ceramics production.

Early uses of tile

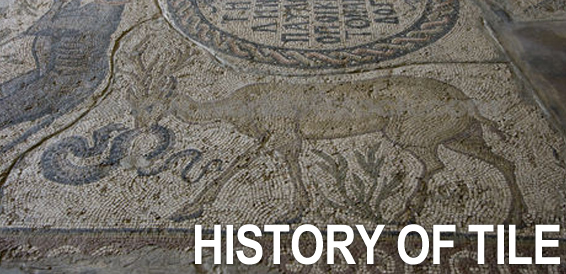

The use of tiles for wall and floor coverings existed in Egypt as long ago as 4000 BC and by 900 AD decorative tiles had become widely used in Persia, Syria and Turkey. As transport and communication developed, the use and manufacture of tiles spread across Italy and Spain and exports were made into the rest of Europe by the end of the 12th century.

Modern processes

Gradually the industry developed into a modem, highly mechanized process, becoming more concentrated in the Staffordshire Potteries (England) area where the established skills and processes of the traditional potters greatly fostered the development of the present ceramic tile. Tunnel kiln firing cycles were measured in days.

The turn round time of a tile bottle oven was at least ten days. In the latter half of the 19th century the forerunners of the present tile manufacturers began to patent a number of different processes for producing ceramic tiles. By the end of the century it was said that no home, public building, hotel or institution was complete without ceramic tiles.

During World War ll many companies were closed and a very different industry emerged. The market- place in the 50’s and 60’s demanded near- perfect quality, sizing and shading.

Tile manufacturing today

A technology known as “roller hearth” now provides the latest generation of kilns. Tiles are conveyed through the kiln as a single layer on a bed of rotating rollers. Only the tiles need to be heated, there are no kiln cars and no supports. Clean natural gas enables burning to take place immediately adjacent to the ware, both above and below, with very precise temperature control. This precise control, together with powerful hydraulic presses, has made possible the manufacture of a new product: the “homogeneous” or “porcelain” fully vitrified tile. Homogeneous tile is impervious, very strong and suitable for very heavy-duty purposes. Roller hearth single layer technology necessitates much shorter firing cycles to achieve required output. One hour, or less, is now typical. Today’s products are mostly mass-produced, to extremely high standards of design and quality.